- guarantee fuel: brown coal

- wide output series: 19, 25, 28, 32, 38, 42, 49, 60 and 76kW. (60 and 76kW 4th class)

- a large-capacity fuel tank. 19 - 38 kW: 330 liters; 42kW: 510 liters; 49 - 76kW: 530 liters

- the possibility of opening the tank cover (180 °)

- the height of the flue pipe 1010 mm from the ground to the flue pipe axis

- right and left versions of the fuel tank

- Energy efficiency class: B for combustion of coal

We developed this boiler based on the best characteristic of our boilers.

Main advantages includes:

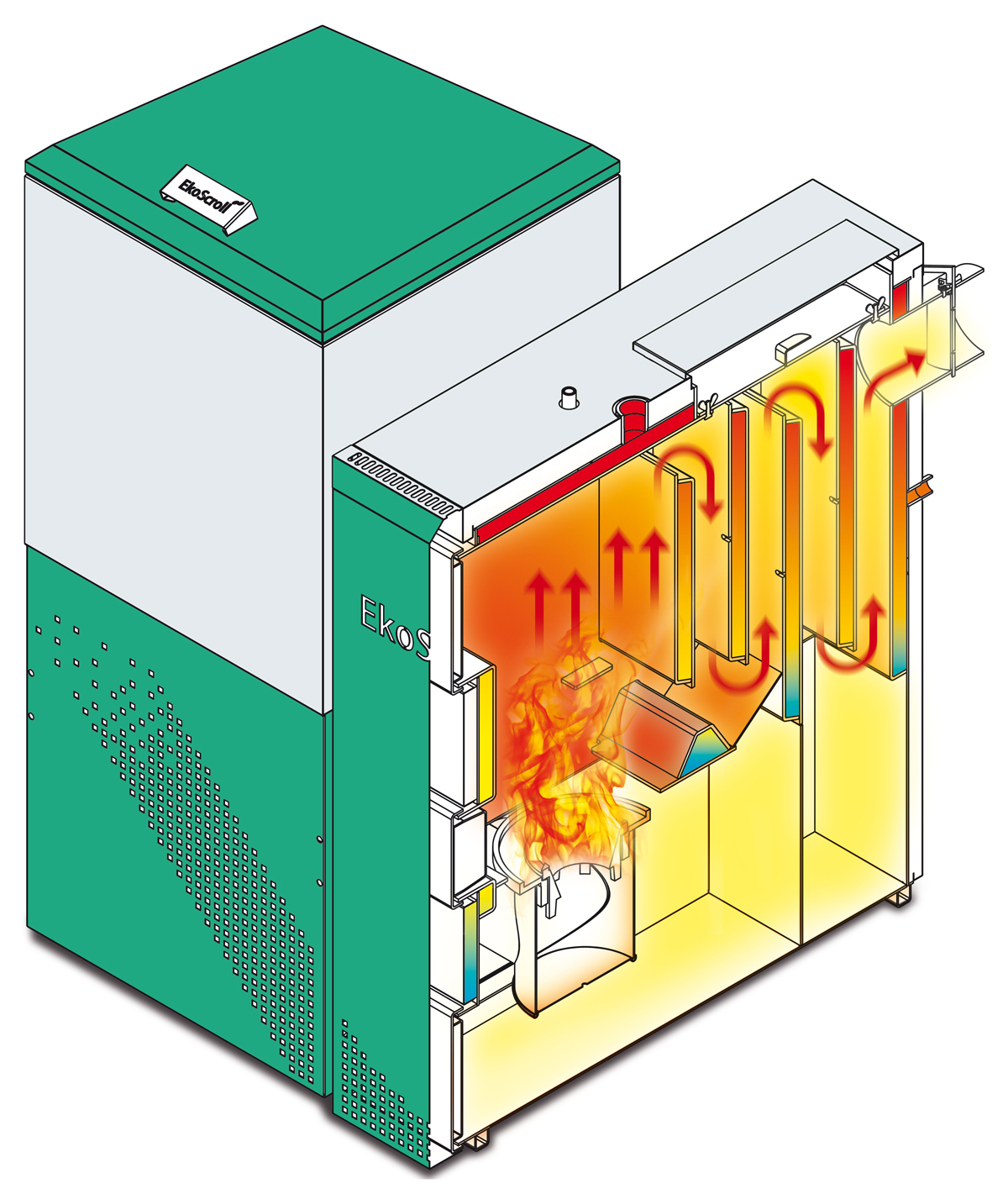

- High efficiency is up to 93.1%. We have achieved this efficiency thanks to the original 5-stroke design of the heat exchanger. The length of the flue path of this boiler far outstrips the other boilers on the market.

- Low emission values ensure classification in the emission class 5 according to ČSN EN 303-5.

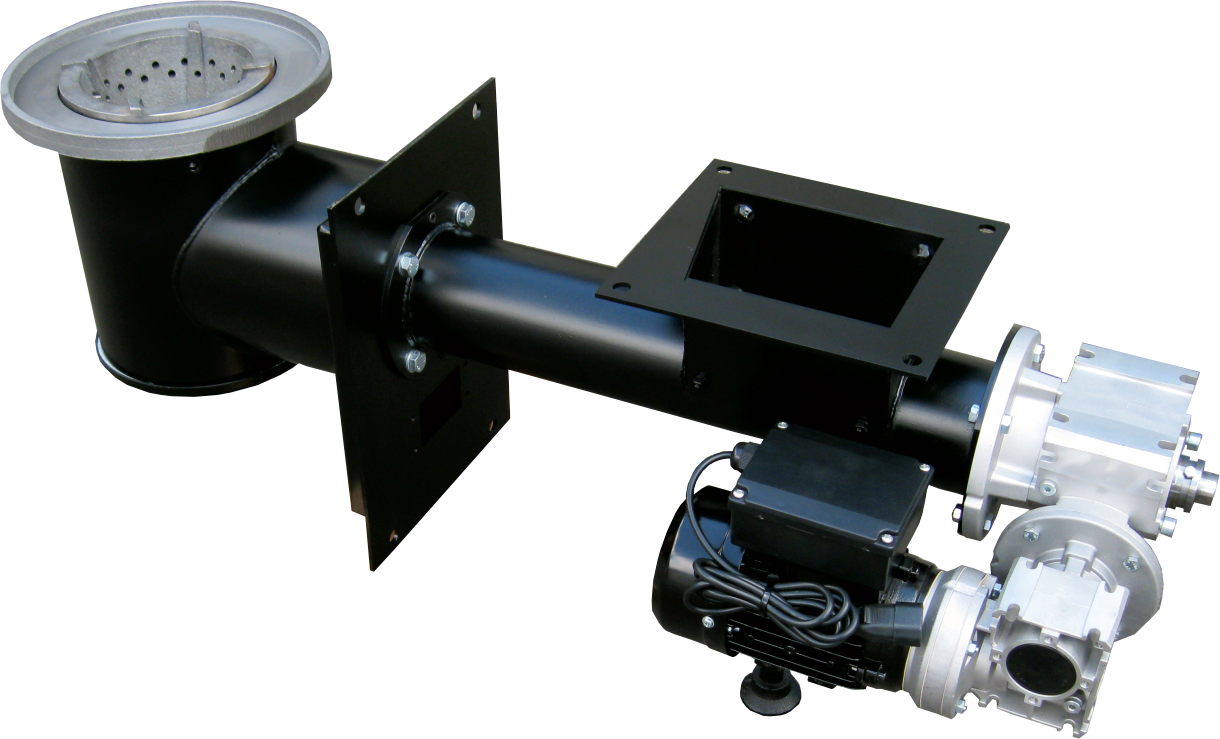

- Used universal cast iron burner with rotating retort allows firing of brown coal. Thanks to the rotating retort, the burner has no problems with the resulting slag during combustion and the lower quality fuel.

- The body of the boiler is made of 6 mm sheet steel. The original design with four vertical heat exchangers guarantees a long service life, high efficiency and minimal cleaning and maintenance requirements. When the body of boiler is produced, precision CNC burning lasers are used. Welding is done using state-of-the-art technologies, including the use of welding robots.

- Last but not least, emphasis is placed on modern boiler design.

- Wide range of output. We produce ALFA boilers at 19, 25, 28, 32, 38, 42, 49, 60 and 76 kW.

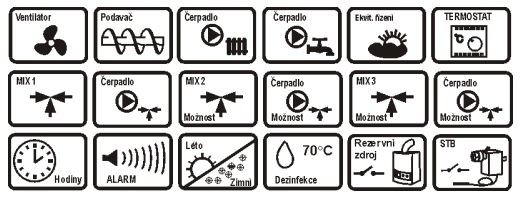

- The control units provide boiler operation with minimal operator requirements. The boiler can be fitted with an equithermal sensor.

- The capacity of the fuel tank 340 liters (goes with the boilers up to power 38kW) allows you to feed the tank once in a week .

- The fuel tank can be positioned to the right or left.