- automatic ignition and extinction of the pellet burner

- efficiency up to 93.9%

- low energy consumption ( 14 kW - 23 W, 18 kW - 28 W, 25 kW - 33 W )

- low fuel consumption ( 14 kW - 3,2 kg / hr, 18 kW - 4,11 kg / hr, 25 kW - 5,5 kg / hr )

- simple design of boiler and burner

- a 325-liter high capacity pellet container

- wide output line: 4,2-14 kW, 5,4-18 kW, 7,5-25 kW , 8,4-28 kW, 11,1-37 kW, 14,9-49,9 kW, 16,8-56 kW

- both right and left version of the pellet container, with the possibility of identifying the side according to the assembly site

- easy cleaning of the boiler and burner heat exchanger

- automatic power modulation of the burner

- the boilers were certified at SZU Brno

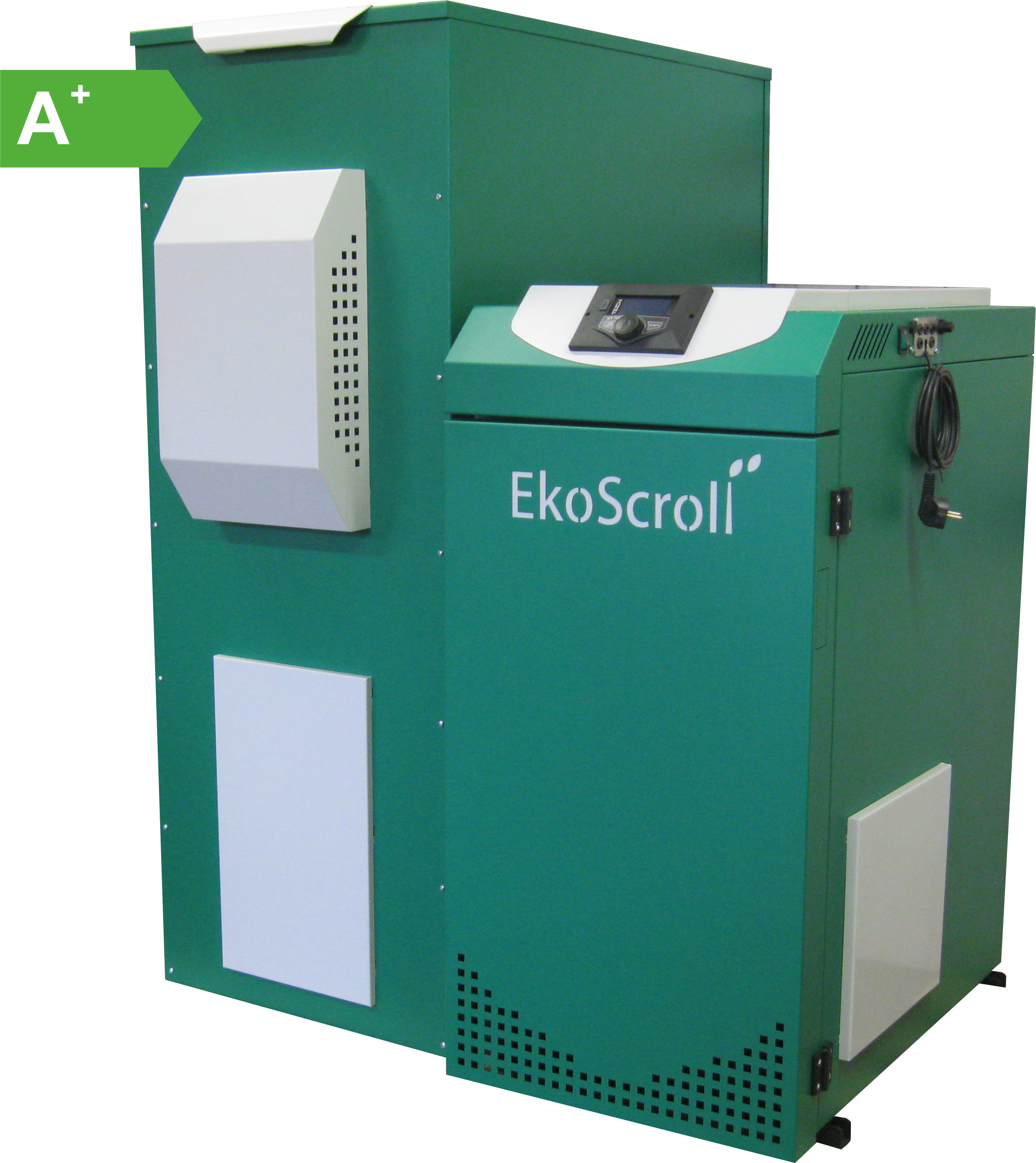

- energy efficiency class: A +

- you can choose between two kinds of the pellets burner

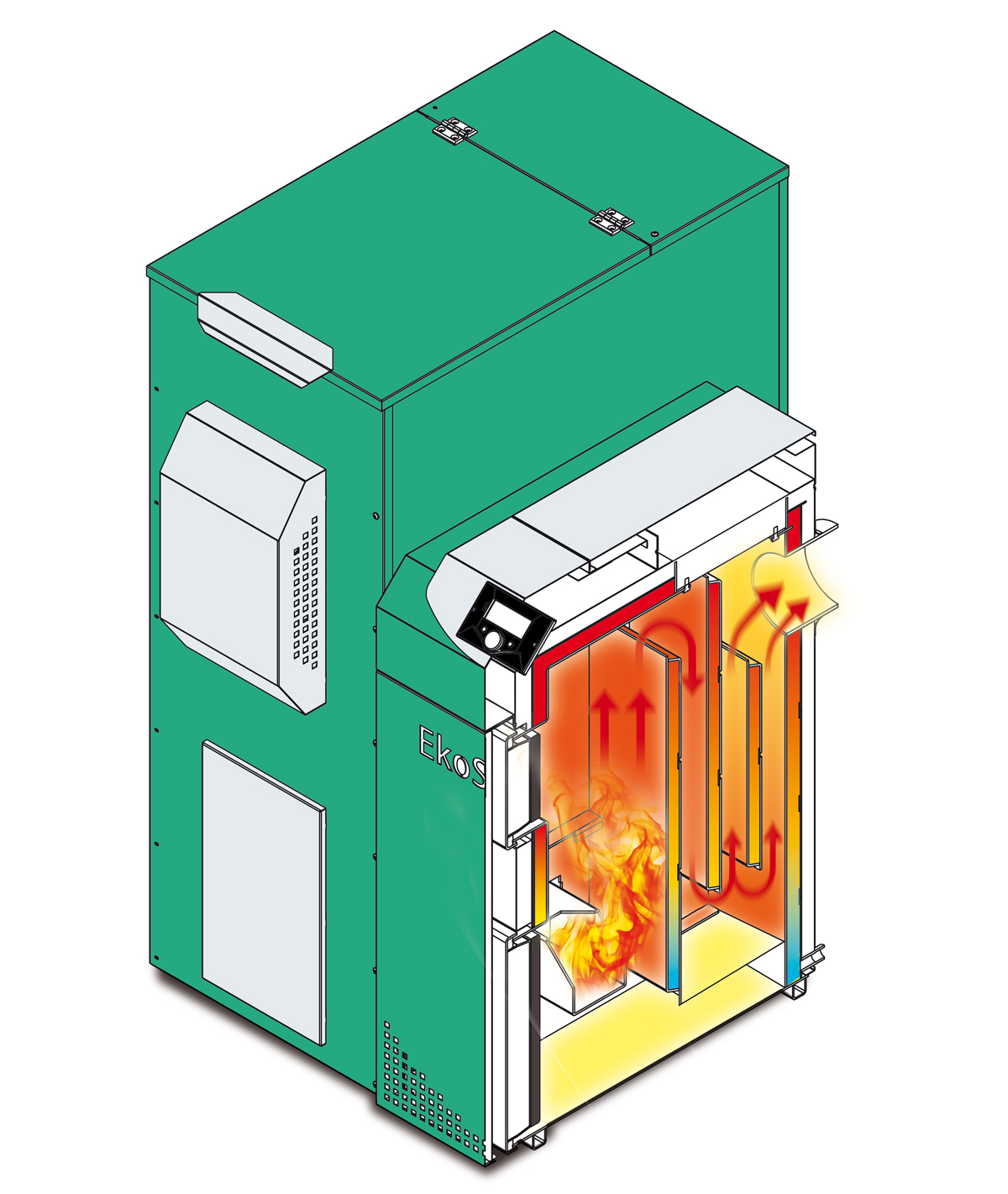

The automatic boiler is a wooden pellet boiler with a steel heat exchanger.The original design of the boiler, the high-quality material used and the protection of the combusting chamber with cast-iron plates ensure the long life of the boiler.

Description of boiler operation:

The 325-liter high-capacity fuel tank incorporates a fuel feeder, which feeds fuel into the burner. The control unit automatically reduces the burner output depending on the water temperature in the boiler exchanger and, based on the communication with the room thermostat, the burner is automatically extinguished and re-ignited. If the wi-fi module is used, the boiler can be controlled and via the Internet and you can also change the parametres via The Internet.

The boiler works with minimal power consumption and minimal fuel consumption. The power consumption and fuel consumption you can be found in technical data.

We produce these automatic boilers in a output line 14, 18, 25, 28, 37, 49 and 56 kW.